Minimum Bend Radius Plastic Sheet

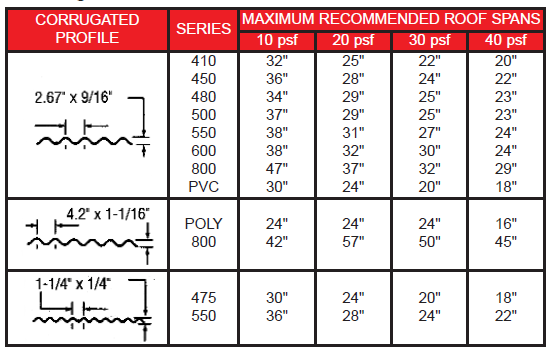

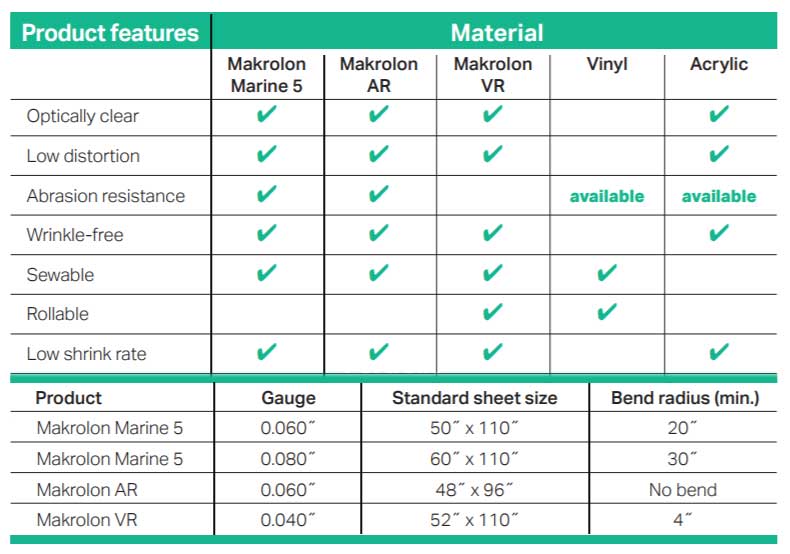

Use this document to choose values that are both manufacturable and meet your needs.

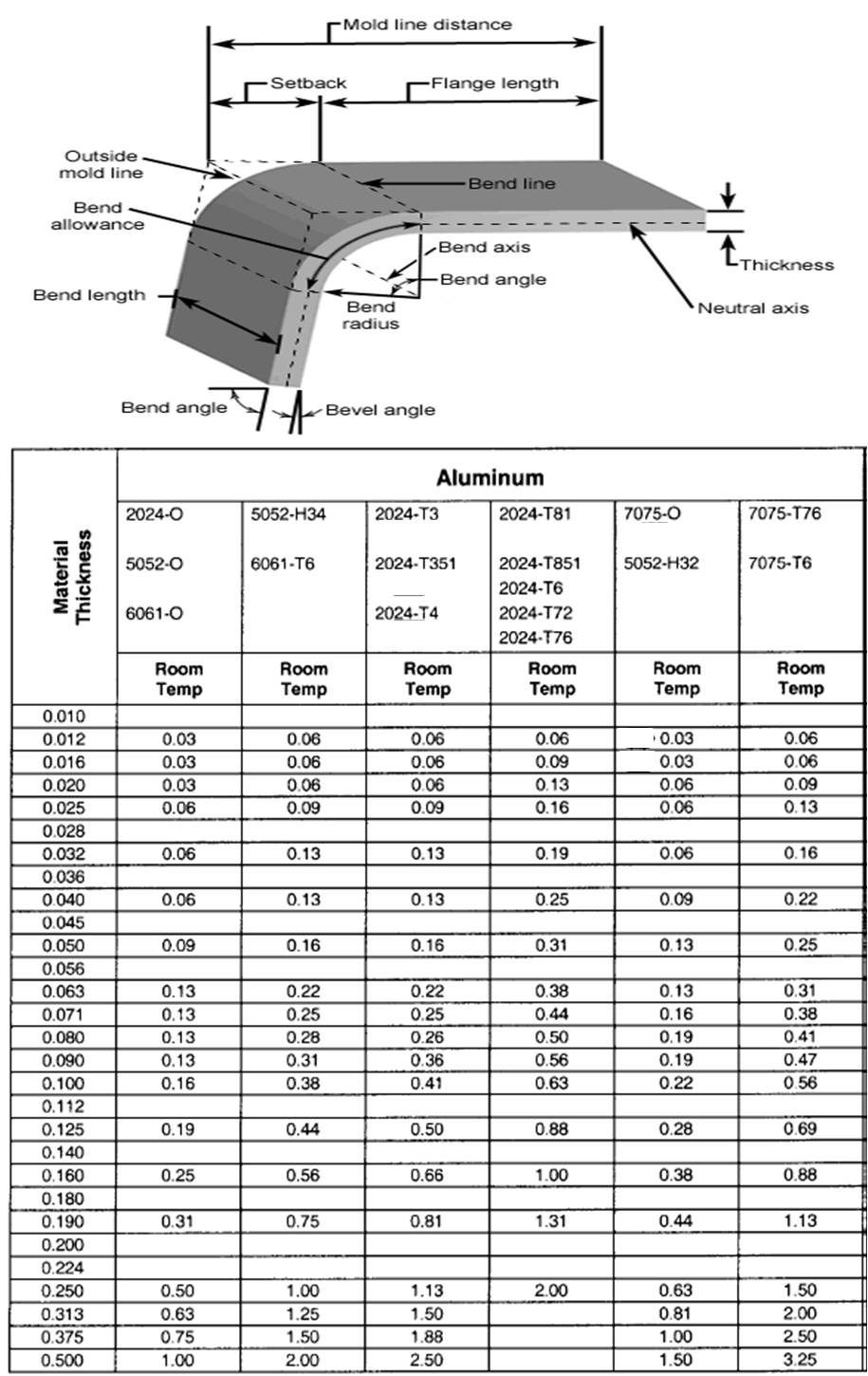

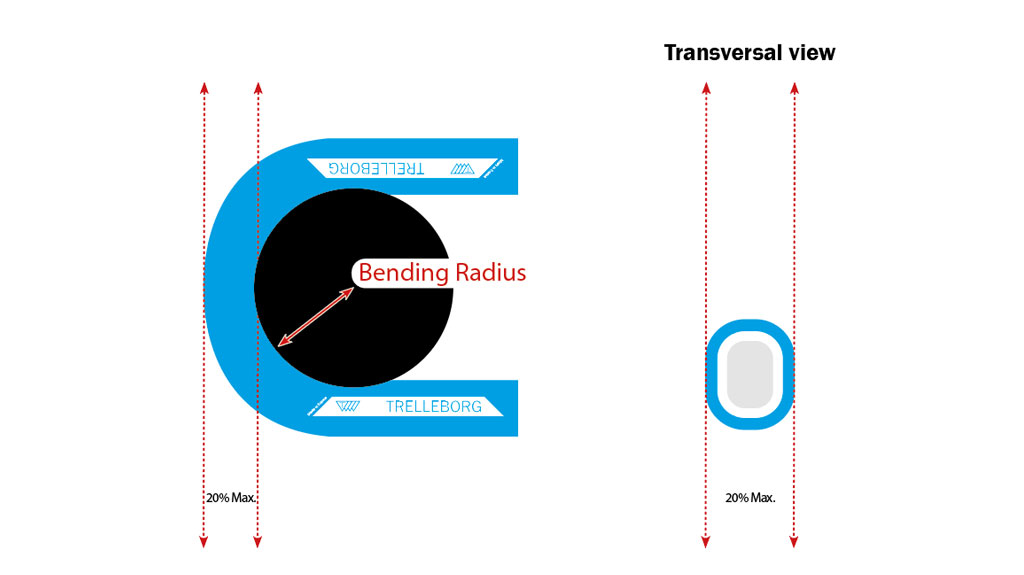

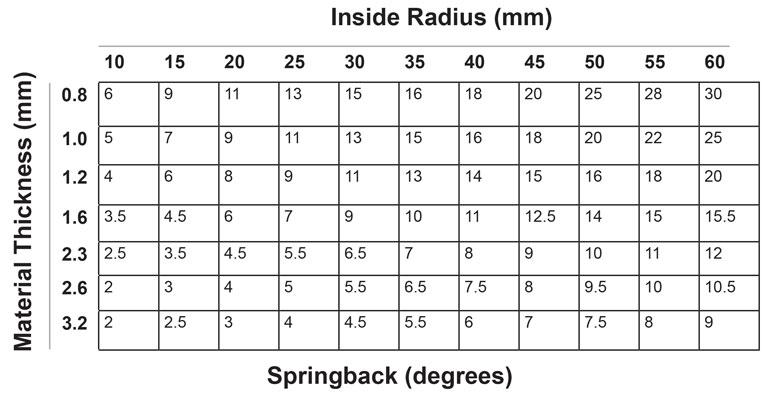

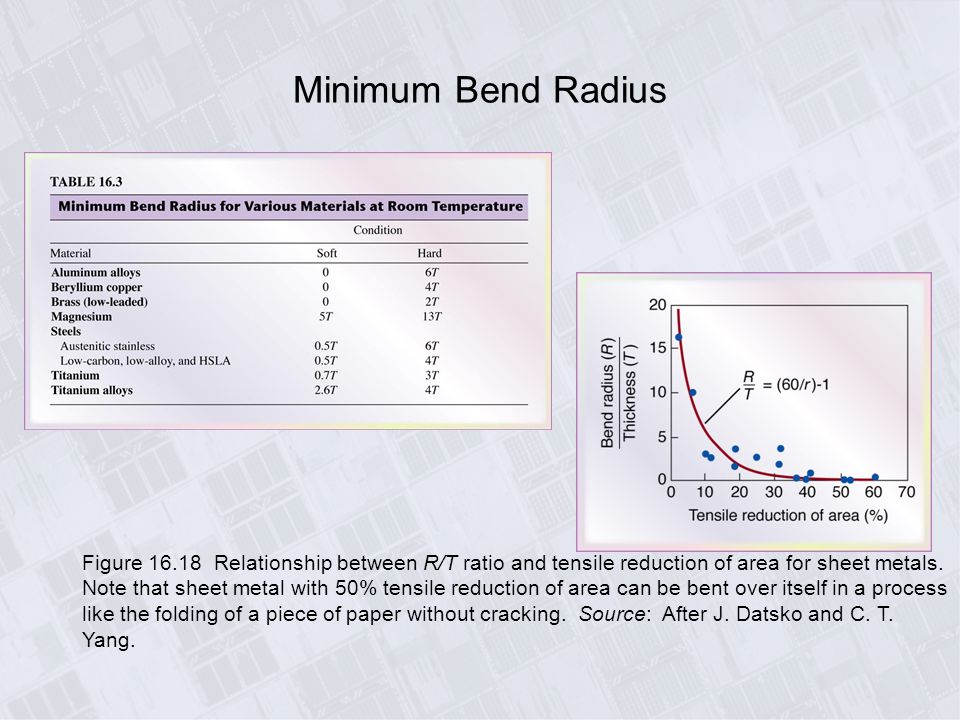

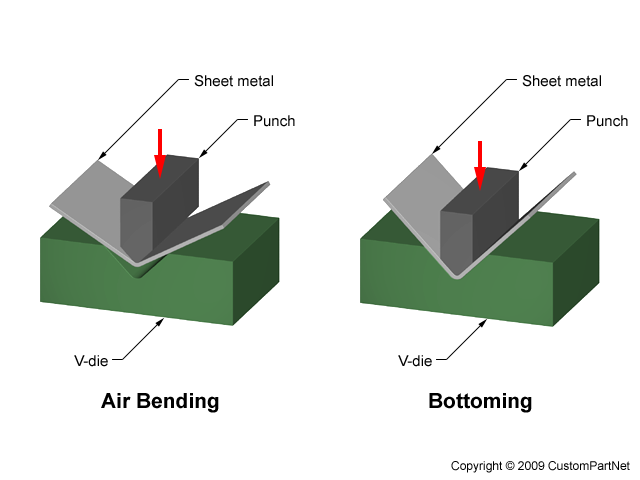

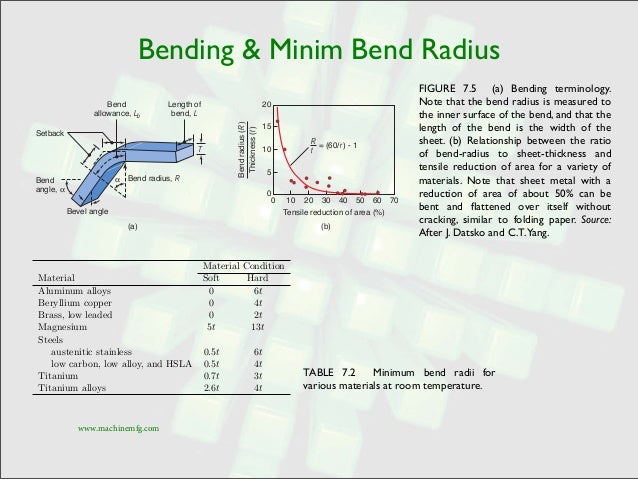

Minimum bend radius plastic sheet. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal. Bend radii minimum bend sizes. The recommended radius of curvature should be a value greater than 180 times the thickness of the sheet for plexiglas g sheet and 300 times the thickness for plexiglas mc sheet see table below. Unfortunately sheet metal bending is not always going to be the same in every shop.

Again the minimum inside bend radius is even larger when bending with the grain. Never heat acrylic sheet in a kitchen oven. As a guideline the material can be radiused to 100 times the thickness. But for harder materials e g.

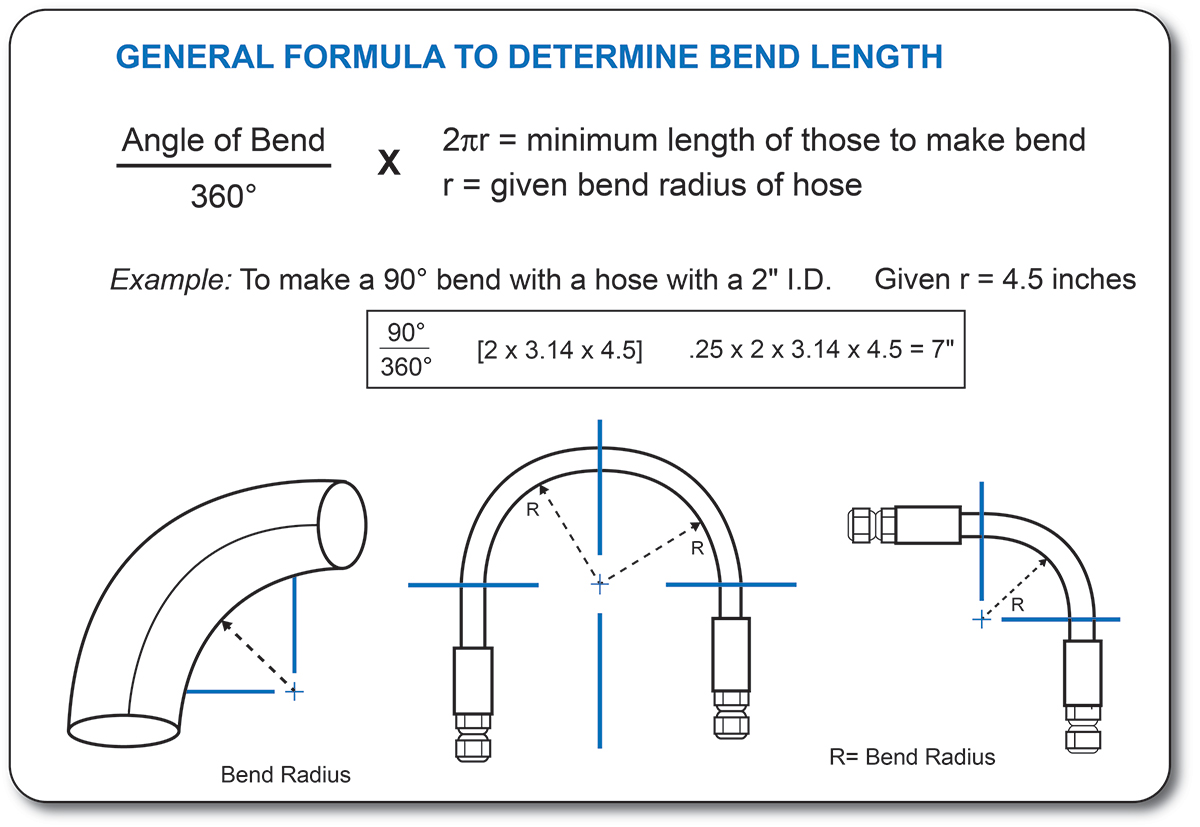

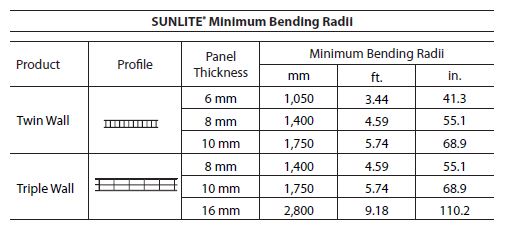

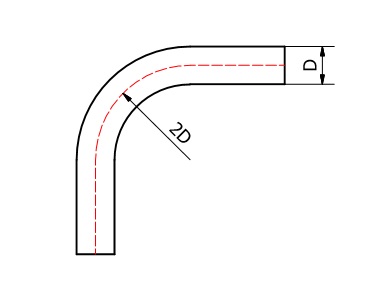

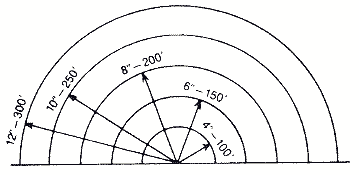

Minimum inside bend radius for sheet metal recommended inside bend radius for sheet metal parts should be equal to material thickness. The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Cold bending tuffak gp polycarbonate sheets may be cold bent with the minimum radius based upon the sheet thickness. The leg lengths are the part of the flange which is outside of the bend radius.

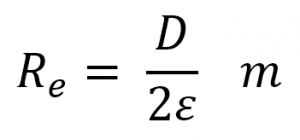

Line bending or thermoforming a brasion resistant acrylic sheet is not recommended. Minimum cold forming radius sheet thickness x 100. Tighter radii may result in crazing or cracking of the coating. It is given by multiplying the thickness of the sheet by 100 i e.

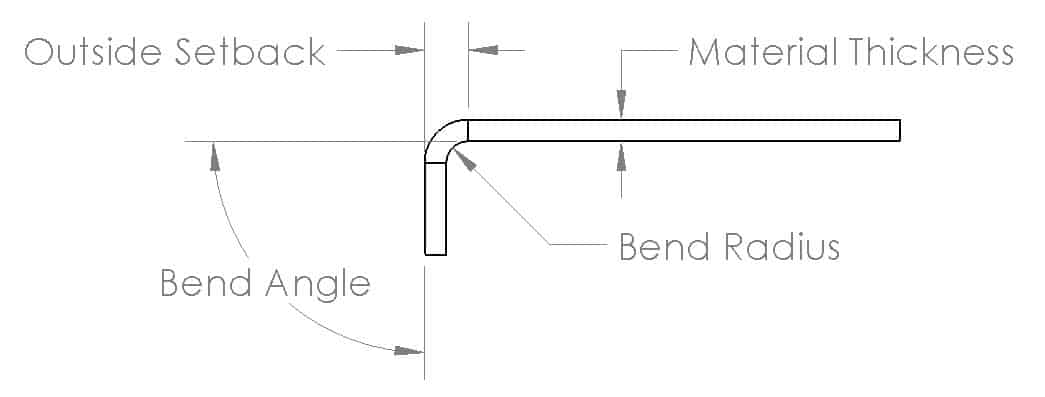

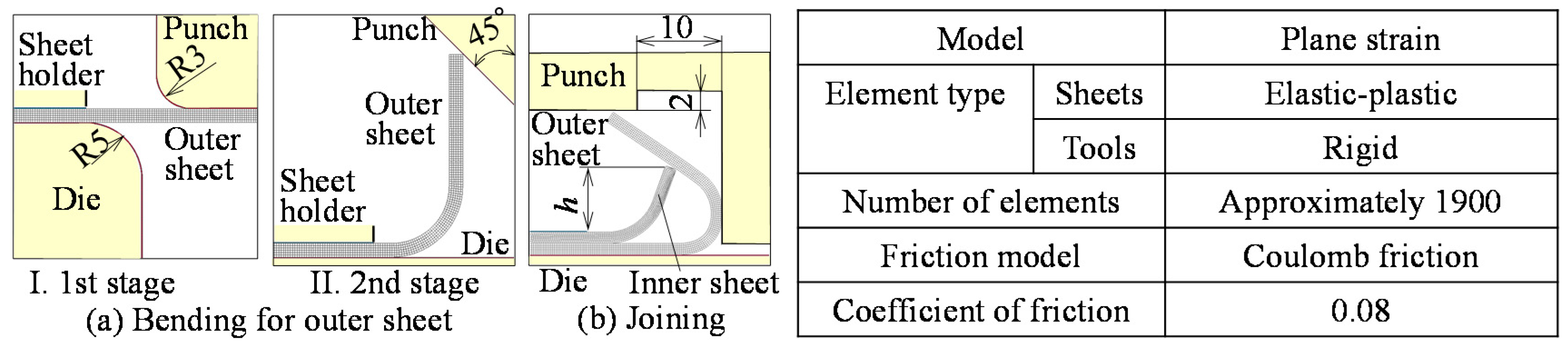

The minimum bend edge dimension l in the figure is the minimum bend edge dimension of one bend edge plus t t is the material thickness and the height h should be selected from commonly used plates such as 0 5 0 8 1 0 1 2 1 5 2 0. The bend allowance is defined as the material you will add to the actual leg lengths of the part in order to develop a flat pattern. In steel between 0 5 and 0 8 in. This radius is applied in all cold bending procedures.

Thick grade 350 and 400 may have a minimum bend radius of 2 5 times the material thickness when transverse bending while longitudinal bending may require a minimum bend radius that s 3 75 times the material thickness. Generally this height is not suitable for selecting a higher size. Cold forming is possible. This gives the minimum radius that should be attained if the final form is to remain in place.

It is most economical to use a single bend radius throughout the design but if necessary you can utilize multiple radii. To calculate the minimum bend radius of curvature multiply the thickness of the sheet to be used by 330. Crca inside bend radius equal to 0 65 times of sheet thickness is also enough.